Detecting refrigerant leakage within the circuit can pose significant issues:

- Moisture loss within the circuit leading to acid formation.

- Ingress of air into the refrigeration circuit.

- Oil leakage along with Freon from the point of escape.

- Potential compressor overheating and seizing due to oil deficiency.

- Risk of compressor winding combustion due to acid presence in the circuit.

- These consequences directly impact equipment longevity, operational efficiency, and associated maintenance costs.

Locating a leak is challenging as it can occur in various places, including pipelines and crucial equipment components, often difficult to access due to structural constraints. Given that refrigerant replacement is costly, timely leak detection and prevention are paramount.

Several effective techniques exist for leak detection in the refrigeration circuit:

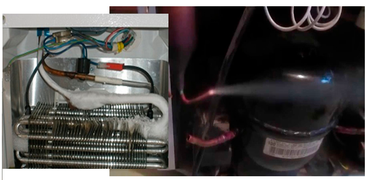

- Visual inspection for oil stains on valves or pipes.

- Application of a soap solution.

- Immersion in ordinary water.

- Use of halogen, electronic, or ultrasonic leak detectors.

- Addition of ultraviolet dye within the system.

- High-pressure leakage detection.

- Using a soap solution for leak detection is particularly effective when the suspected leak location is known, such as during repair or component replacement. This method's advantages lie in its simplicity and cost-effectiveness. A homemade soap solution, made with dishwashing detergent or regular soap, suffices. Alternatively, commercial options like aerosol-packaged soap solutions with various additives are available in stores, sometimes sold with pads for convenience.

Write a comment